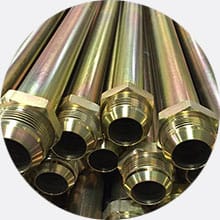

Zinc Plating

How Zinc Plating Works

Zinc plating protects metals such as steel against corrosion. We use electrodeposition to add a thin coating of zinc metal to another metal object, or substrate.

The zinc coating protects the underlying metal surface with a thin barrier that keeps rust from reaching the other surface. The zinc coating is sacrificial coating. The zinc will corrode first instead of the metal substrate that it protects.

Besides its excellent protection against corrosion, some of the zinc advantages include:

Chemical Conversion

Chromate conversion coatings, sometimes referred to as chemical conversion, refer to the process of applying a thin barrier coating to passivate zinc plated substrates. The chromate coating is a thin inert layer with self-healing properties that protect the substrate, boosting corrosion protection, improving electrical conductivity, and providing excellent paint adhesion.

Eco Finishing offers a selection of different chromate conversion coatings. The type of chromate you choose will depend on the final use for the parts. Hexavalent chromates provide a superior level of corrosion protection; however, usage of hexavalent chromium present in these products has been reduced due to regulations such as RoHS. Trivalent conversion coatings are RoHS compliant as they do not contain hexavalent chromium.