Electroless Nickel Plating

Electroless Nickel Plating Expertise at your Service

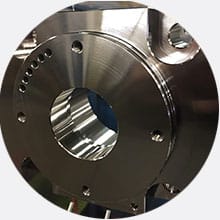

Electroless nickel plating is an auto-catalytic reaction that deposits an even layer of phosphorous nickel alloy on the surface of a solid material (substrate), like metal or plastic. Our plating process starts with dipping the material in a plating solution bath. Once submerged, a reducing agent reacts with the material’s ions to deposit the alloy.

Electroless plating is different from electroplating in that it does not require passing an electric current through the plating solution to create a coating on the substrate. The electroless nickel plating process deposits a reliable, repeatable nickel coating of uniform thickness. This process eliminates the uneven buildup typical of other electroplating processes that can compromise threads and part tolerances that lead to post-plate grinding.

Understanding Phosphorus Content

The phosphorus content of an electroless nickel finish depends on the level of corrosion protection you need for the substrate. Medium-phosphorous electroless nickel is the standard electroless nickel process. It provides a balanced combination of wear resistance, corrosion protection, lubricity, and affordability. High-phosphorous electroless nickel, on the other hand, offers increased corrosion protection, most resistant to acidic environments.

Electroless nickel provides excellent corrosion protection, solderability and lubricity, and effectively coats parts with sharp edges, deep recesses, seams, threads and complex geometries. Some typical applications include:

• Automotive and aerospace components

• Electrical equipment

• Molds and dies

• Foodservice equipment

• Gas and oil components

• Printing industry equipment

• Packaging and handling machinery

• Salvage applications